Laminated Solid Linings |

|

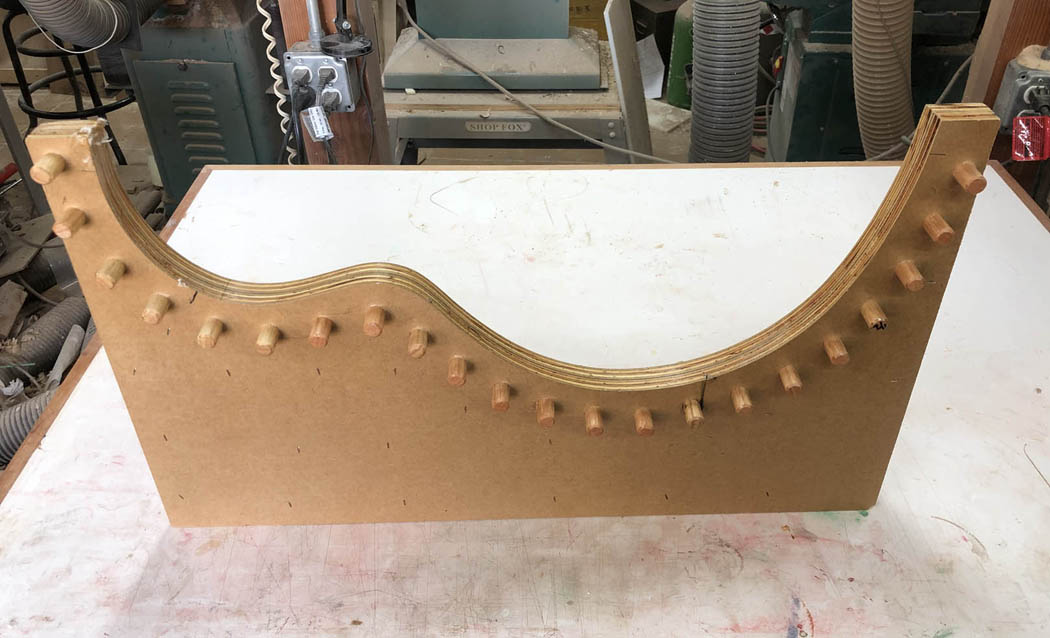

Here's how I make laminated solid linings. I bought a 500' roll of 15/16" maple edge binding, unglued. I estimate I'll get about nine guitars worth of linings from it. It's 0.5mm thick so I use ten layers of it to make 5mm thick liners. I glue it up with epoxy, using System Three Clear Coat because it is relatively low viscosity. I made this mold from 1" plywood and 1/2" oak dowels. I finished the mold with polyurethane and waxed it to help keep any epoxy spills from sticking to it:

I cut a 4" wide strip of thin plastic sheet to keep the epoxy contained. I cut the 10 strips of edge banding, brush epoxy onto each and stack them up, and wrap them in the plastic. Then I put the stack into the mold and rope it down with a strip of bicycle inner tube:

Once the epoxy has cured, I remove the lining, clean it up with disk and spindle sanders, and rout a 1/8" radius edge on the inside edges:

I cut an 8mm strip of lining off of each edge with this bandsaw jig. This gives me one top and one back liner for one side:

I made a similar mold to make my cutaway linings. One set from it plus two sets from the main mold produces a full set of linings for one guitar:

Here they are installed:

|

E-Mail Me

or call (503)688-3376