Truss Rods |

|

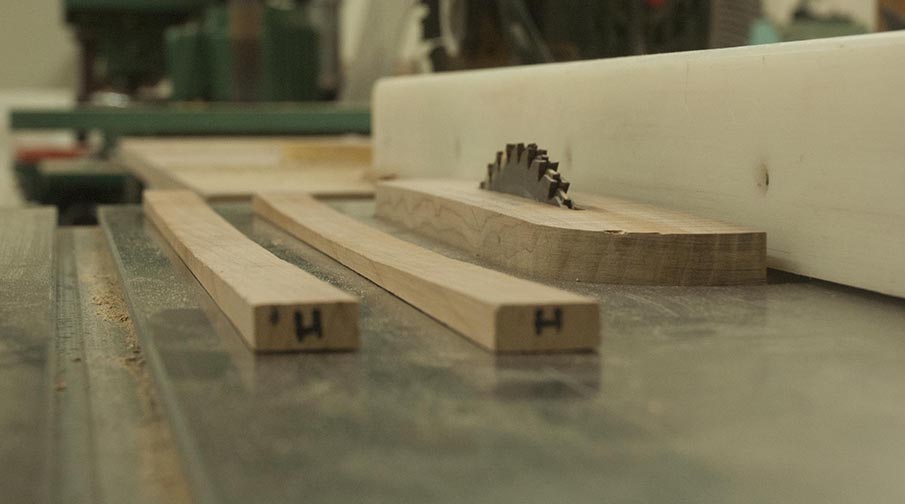

Here's how I make my truss rods. I cut a curved slot in the neck with this jig on my table saw. It consists of a raised insert with a curved top surface, and a pair of slats with the same curve which attach to the neck with double-sided tape. I mount three blades on the saw to cut a roughly 1/4" wide slot. The slats and insert make the resulting slot curved, with the deepest point at roughly the center of the neck.

The rods themselves are just a length of pre-threaded 10-32 rod, which go for about 50 cents for a 3' length (which makes two truss rods). I shrink heat-shrink tubing over all of it except the ends. I cut a 1/2" piece of brass rod and pin it in place with a 1/16" drill bit. I cut a little shelf in the brass rod to expose the end of the drill bit. That way I can theoretically pull the pin and pull the truss rod if it ever stripped (although I've never had to do that to date). Note that pre-threaded rod is much less work than cutting threads yourself, and it's actually stronger than a partially threaded rod due to the principle of stress concentration.

I make my truss rod nuts out of steel 5/8" PC board standoffs and 1/4" 10-32 socket head cap screws, fusing the latter into the former with high strength thread lock compound. I add a small washer for the nut to bear against.

I cut a spline to the curve of the rod slot and glue it in over the rod. This presses the rod into its curve. The fretboard is then glued over the whole thing.

|

E-Mail Me

or call (503)688-3376